The CO2 textile laser cutting machine with the wide using area. We support single head, dual head moved each other, multi-heads auto feeding laser cutting machine.

The special auto feeding system and unique automatic correction device to keep the machine with high positioning accuracy and perfect cutting results.

Technical Parameter for Auto feeding 1610 CO2 textile laser cutting machine

Model | LK1610 |

Cutting area | 1600x1000mm |

Laser power | 80W / 100W / 130W |

Laser type | CO2 Laser tube |

Engraving speed | 0-60000mm/min |

Cutting speed | 0-24000mm/min |

Resetting positioning accuracy | 0.01mm |

Power supply | 220V/50HZ 110V/60HZ |

Operating temperature | 0 – 45 °C |

Operating humidity | 5-95% |

Min. shaping character | English 1.0x 1.0mm |

Graphic format supported | PLT, AI, DXF, BMP, DST |

Software supported | CorelDraw, PhotoShop, AutoCAD, TiandaoTajima |

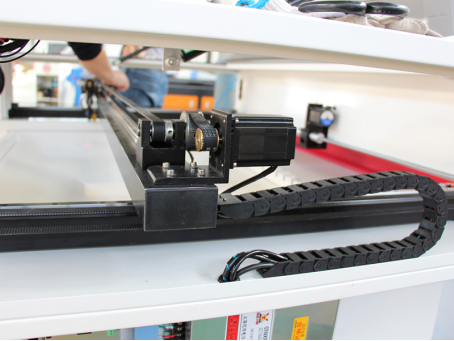

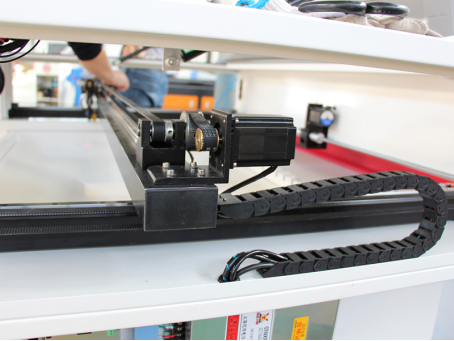

Driving system | Stepper motors |

Cooling mode | Water-cooling and protection system |

Recommended spare parts | Laser tube and lens |

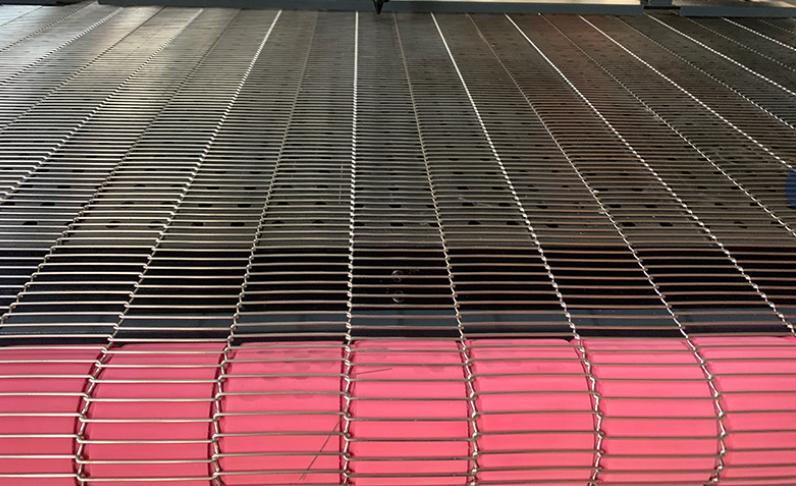

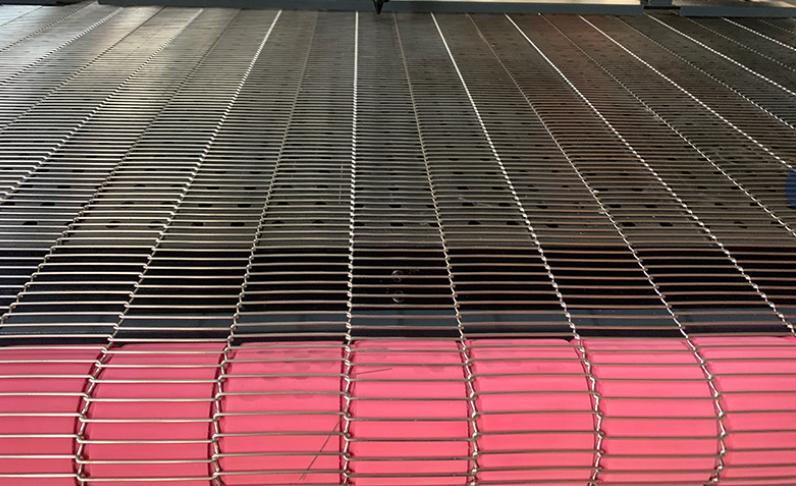

Auto feeding table

The dense auto feeding table could cut for small graphics, the machine mainly cutting for roller materials, such as garment, fabric, leather industries.

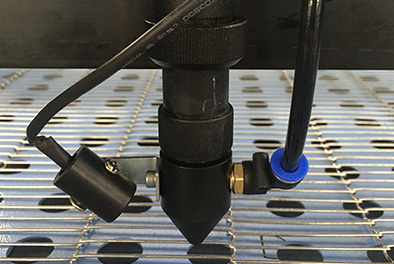

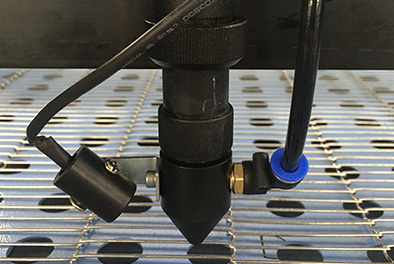

Laser head with red point

Red dot easily and quickly to find working point, more intelligent. It has the advantages of convenient production operation and high production efficiency.

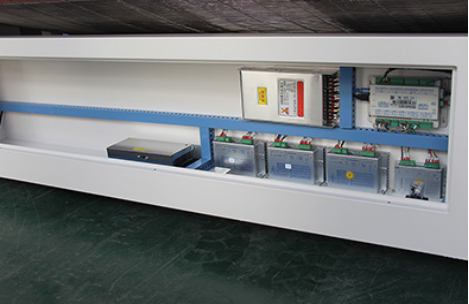

Machine main parts of Auto feeding 1610 CO2 textile laser cutting machine

#* Co2 80-150W laser tube as you need

#* 1600*1000mm working size

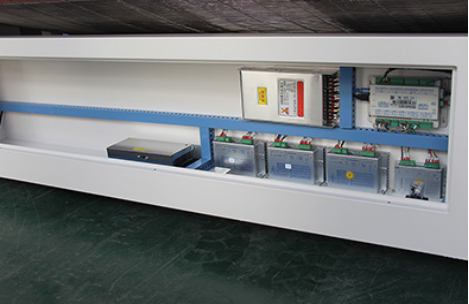

#* Ruida 6445 control system

#* Taiwan CSK imported or Hiwin linear guide rail

#* Imported II-VI mirrors

#* S&A CW5000 etc water chiller

#* YAKO/ Leadshine steppe motor

#* YAKO/ Leadshine driver

#* Red point

#* 550w or more bigger air fan

#* Tool box

Ruida 6445 control system: | Control box : | Laser tube: | Taiwan CSK guide rail: |

Stepper motor:

| S&A CW5000 water chiller: | II-VI lens: | Tool box: |

Applicable materials:

Engraving and cutting for fabric, leather, garment, embroidery, toy, handbag, car mat, foam, etc