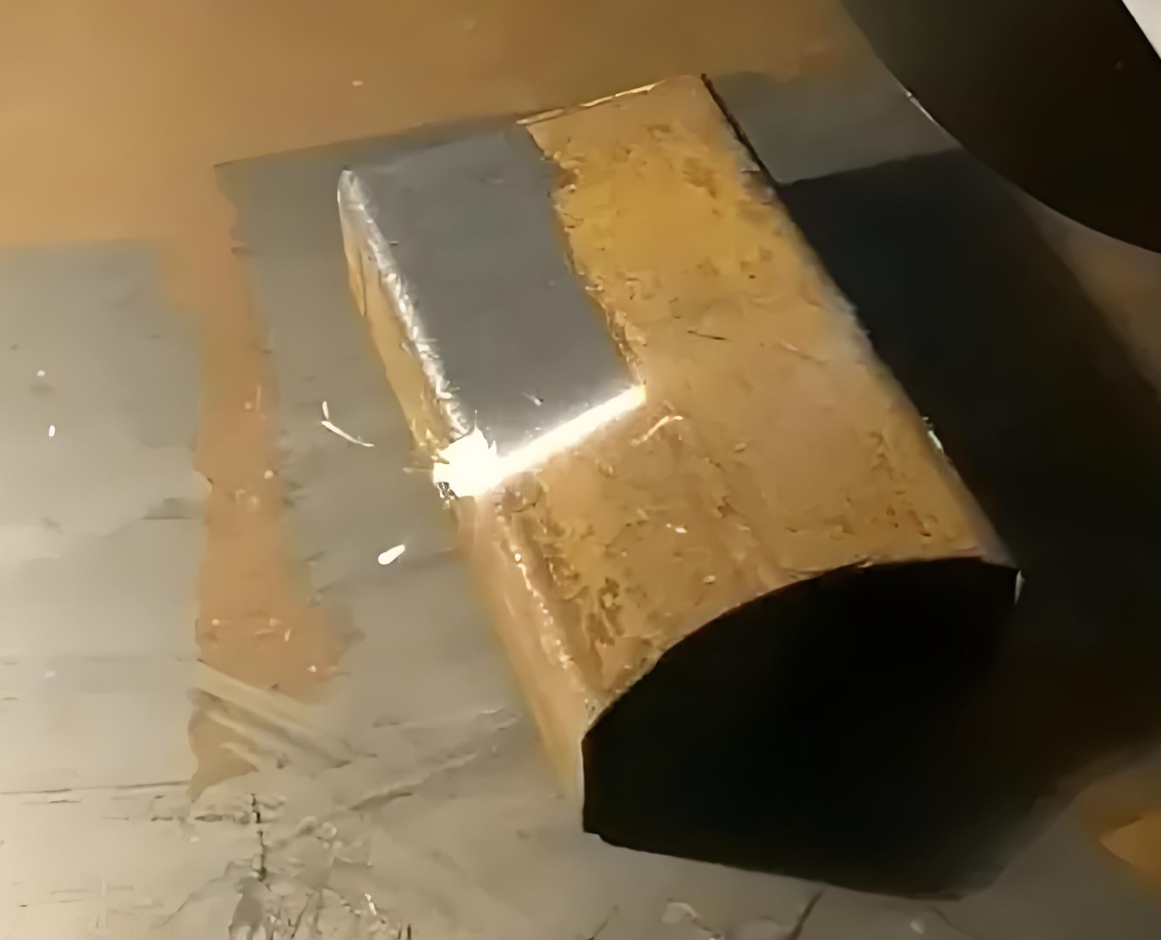

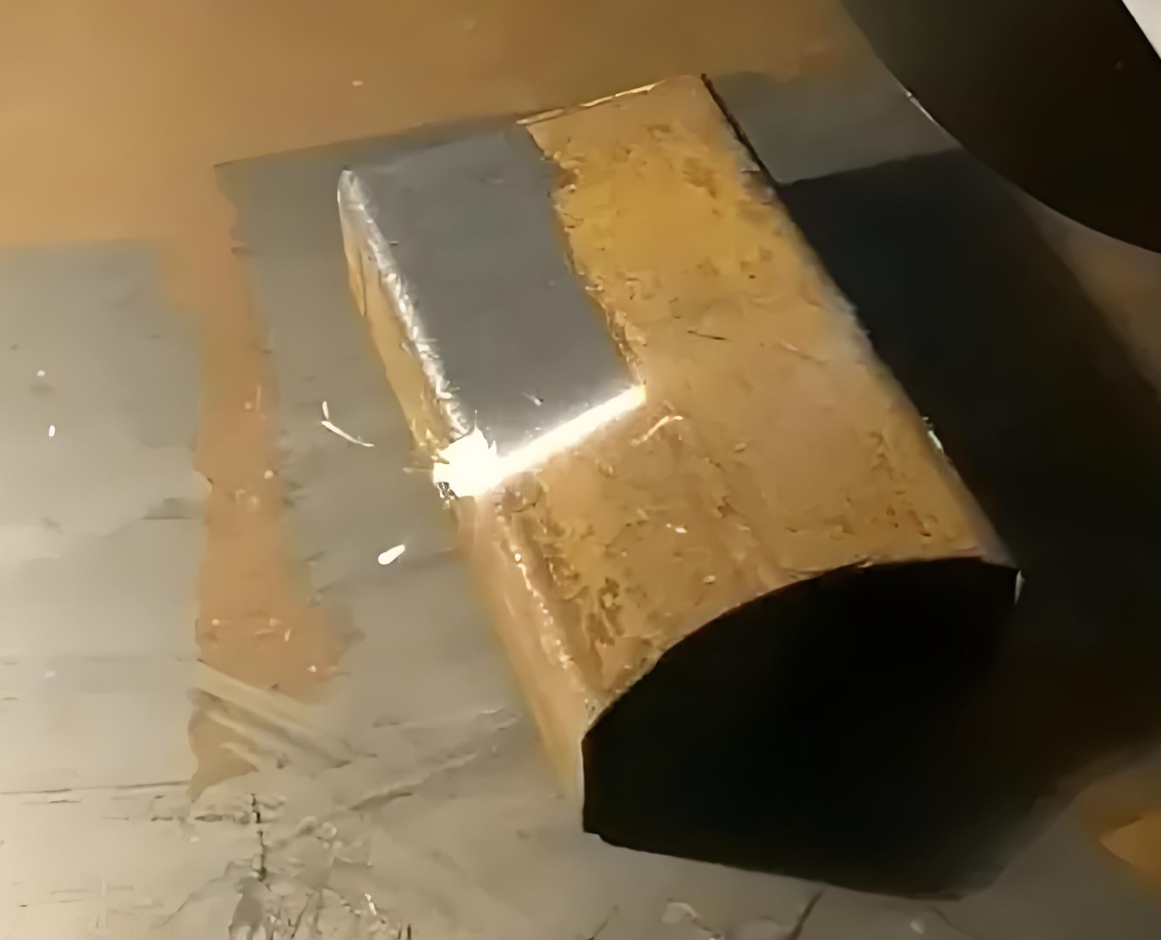

The advantages of laser cleaning machine for rust removal mainly include high efficiency, precision, green and environmental protection, multi-function, automated operation, non-contact cleaning, high cleanliness, flexibility and controllability, low-cost operation, Enhanced roughness control capabilities.

Efficient: Laser rust removal is fast and can quickly remove various rust layers, oxide layers, paint films, etc., and can remove an area of 1 square meter in one minute.

Accurate: Using a high-precision laser beam, can accurately illuminate the rusted area, without causing damage to the object itself after removing the rust layer, and maintaining the surface finish.

Green and environmentally friendly: Laser rust removal does not produce environmental pollution and noise,has no impact on the operator,and does not require the use of chemicals and other harmful substances,complies with environmental protection requirements .

Multifunctional: In addition to rust removal, it can also be used for cleaning, marking, etc. It can effectively clean micron-level pollution particles and achieve controllable fine cleaning. It is suitable for cleaning precision instruments and precision parts.

.

Automated operation: Simple to operate, can accurately remove surface oil stains, rust, coatings, etc., can easily realize automated operations, can be recycled once put into use.

Non-contact cleaning: Laser cleaning machine rust removal is non-contact, can be transmitted through optical fiber, combined with robots or manipulators, conveniently realizes long-distance operation, can clean parts that are difficult to reach with traditional methods .

High cleanliness: can achieve very high cleanliness,is a new application of surface engineering treatment,can effectively remove rust,clean different types of pollutants on the surface of various materials.

Flexibility and controllability: It has strong flexibility and controllability. Through different parameter settings, the same laser cleaning machine can roughen the surface and improve the adhesion; Different laser powers can be set for preset effects. Frequency, aperture, focal length, etc., do not exceed the limit as much as possible, only clean the required range and intensity, improve efficiency and reduce costs2.

Low-cost operation: Rust removal can be used stably for a long time, No consumable materials are required, Only a small amount of electricity is required, Maintenance and operating costs are low.

Enhanced roughness control capabilities: The power and parameters of the laser cleaning machine are highly adjustable, the energy density and cleaning depth of the laser beam can be accurately controlled according to needs,thereby achieving precise control of surface roughness.

These advantages make laser cleaning machines widely used in rust removal and become an ideal rust removal tool. With the continuous development of technology, the application scope of laser cleaning machines will be further expanded, bringing more efficient and reliable rust removal methods to various industries