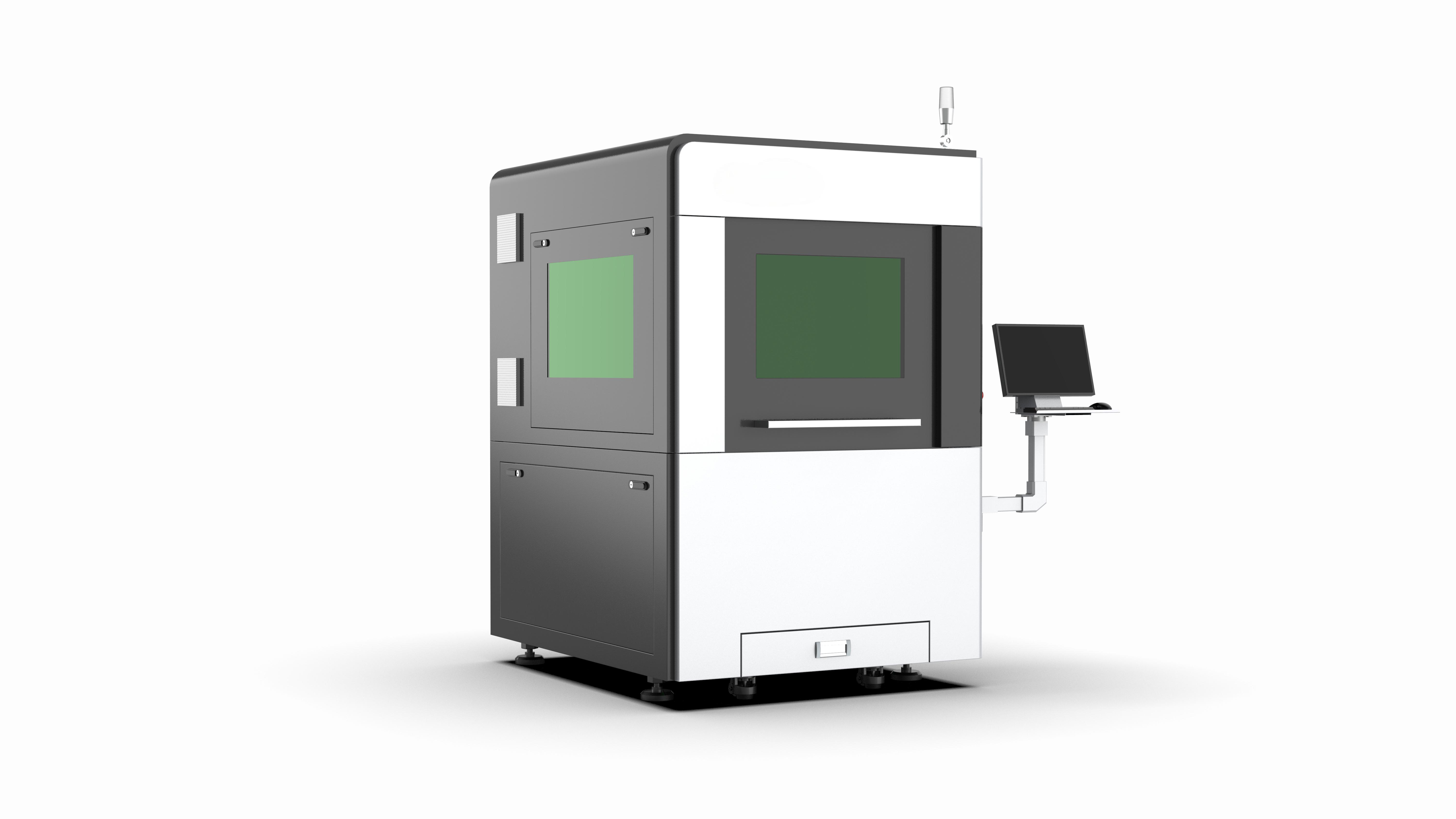

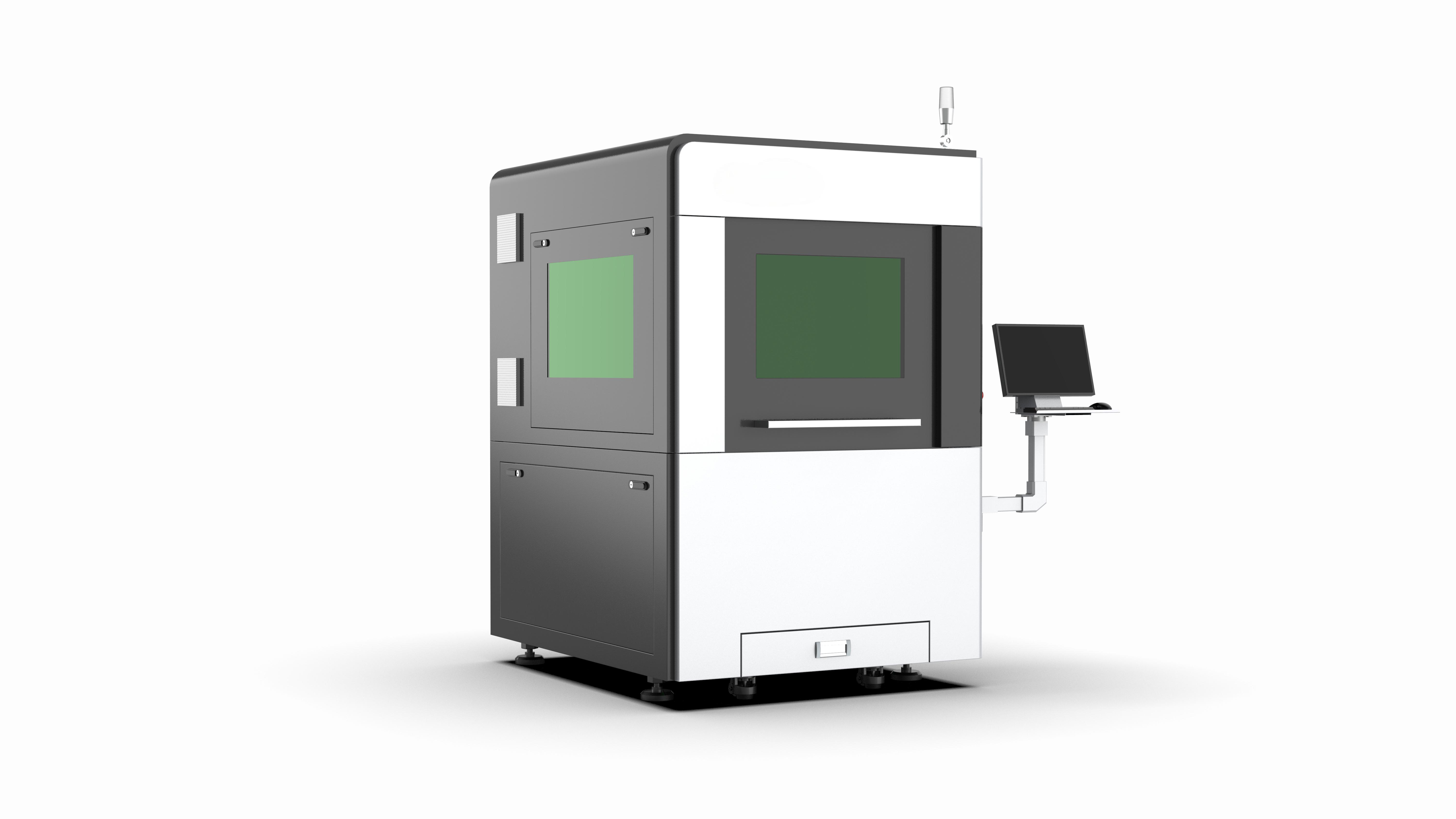

In modern manufacturing, high-precision fiber laser cutting machines are gradually becoming important equipment in all walks of life. They use advanced fiber laser technology and precision motion control systems to achieve high-precision and high-efficiency cutting processes. This article will introduce the technical characteristics of laser high-precision cutting machines and their wide application in multiple industries.

Technical features of high-precision fiber laser cutting machine:

1. Fiber laser technology: High-precision laser cutting machines use fiber lasers as cutting tools. They have the advantages of high energy density, narrow beam

diameter, and high beam quality, and can achieve high-precision cutting of various materials.

2. Precision motion control system: The cutting machine is equipped with a precision motion control system, which can accurately control the movement trajectory

and cutting depth of the cutter head to ensure the stability and consistency of the cutting process.

3. Intelligent control system: The laser high-precision cutting machine is also equipped with an intelligent control system, which can intelligently adjust according to

different cutting requirements to achieve the best cutting effect.

4. High efficiency and high speed: Laser cutting has the characteristics of high efficiency and high speed, which can quickly complete the cutting and processing of

complex parts and improve production efficiency.

5. Wide application: Optical high-precision cutting machines are suitable for cutting and processing of a variety of materials, including metal materials, non-metal

materials, composite materials, etc., and are widely used in automobile manufacturing, hardware manufacturing, mobile phone 3C, aerospace, engineering machinery,

petroleum Chemical industry, medical equipment and other industries.

Application areas of high-precision fiber laser cutting machines :

1. In automobile manufacturing, laser high-precision cutting machines can be used to cut body panels, seat frames, door panels and other parts to ensure the

accuracy and quality of the parts.

2. In the field of hardware manufacturing, laser high-precision cutting machines can be used to cut various metal materials, such as stainless steel, aluminum alloy,

etc., for making hardware products, furniture accessories, etc.

3. In electronic product manufacturing, laser high-precision cutting machines can be used to cut mobile phone casings, screen glass and other components to achieve

precision processing and personalized customization.

4. In the aerospace field, laser high-precision cutting machines can be used to cut high-strength materials such as aircraft structural parts and engine components to

the safety and reliability of aircraft.

5. In engineering machinery manufacturing, laser high-precision cutting machines can be used to cut steel plates of various thicknesses and shapes to produce heavy

machinery parts such as excavators and loaders.

6. In medical device manufacturing, laser high-precision cutting machines can be used to cut metal casings, parts, etc. of various medical devices to ensure product

accuracy and hygienic standards.

To sum up, laser high-precision cutting machines have advanced technical features and wide application fields, providing efficient and precise solutions for production

and processing in various industries, and will continue to play an important role in the future.