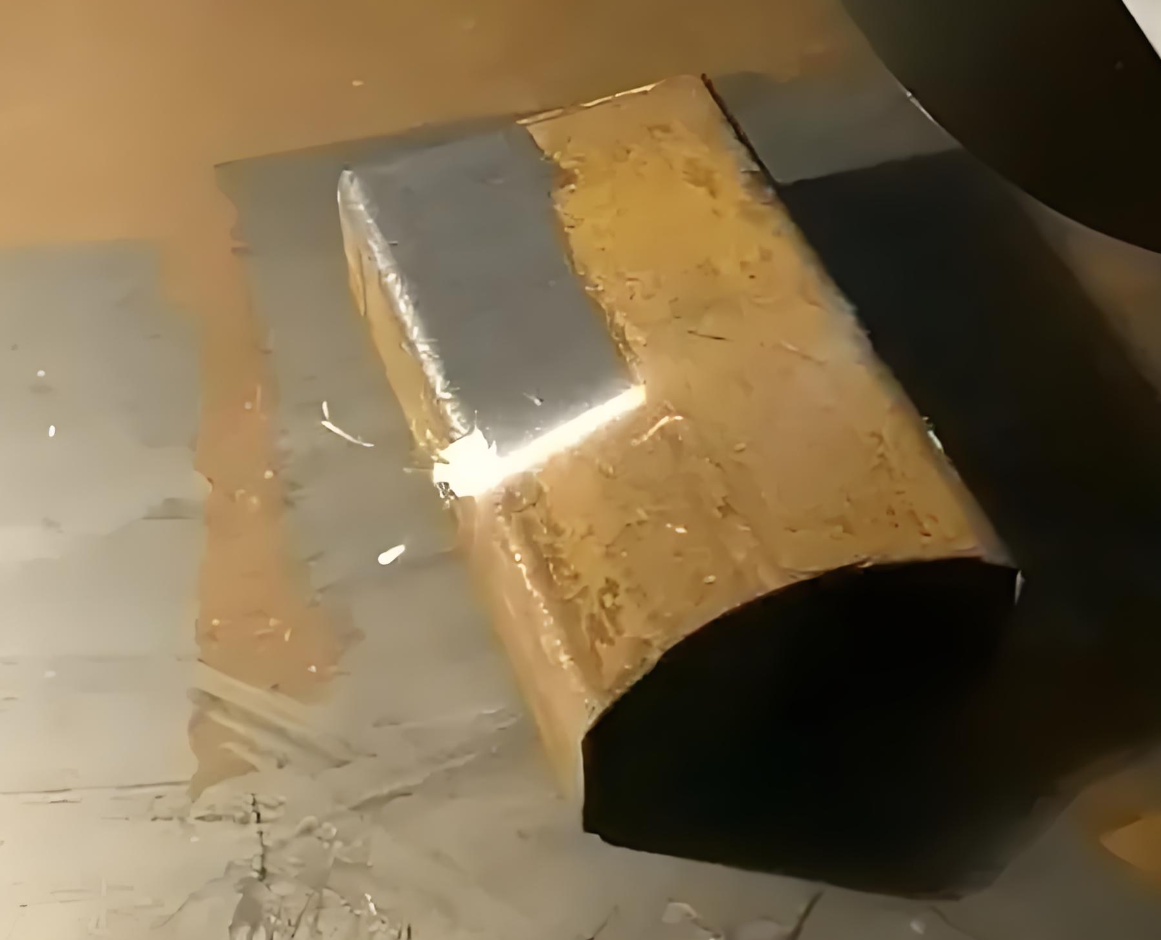

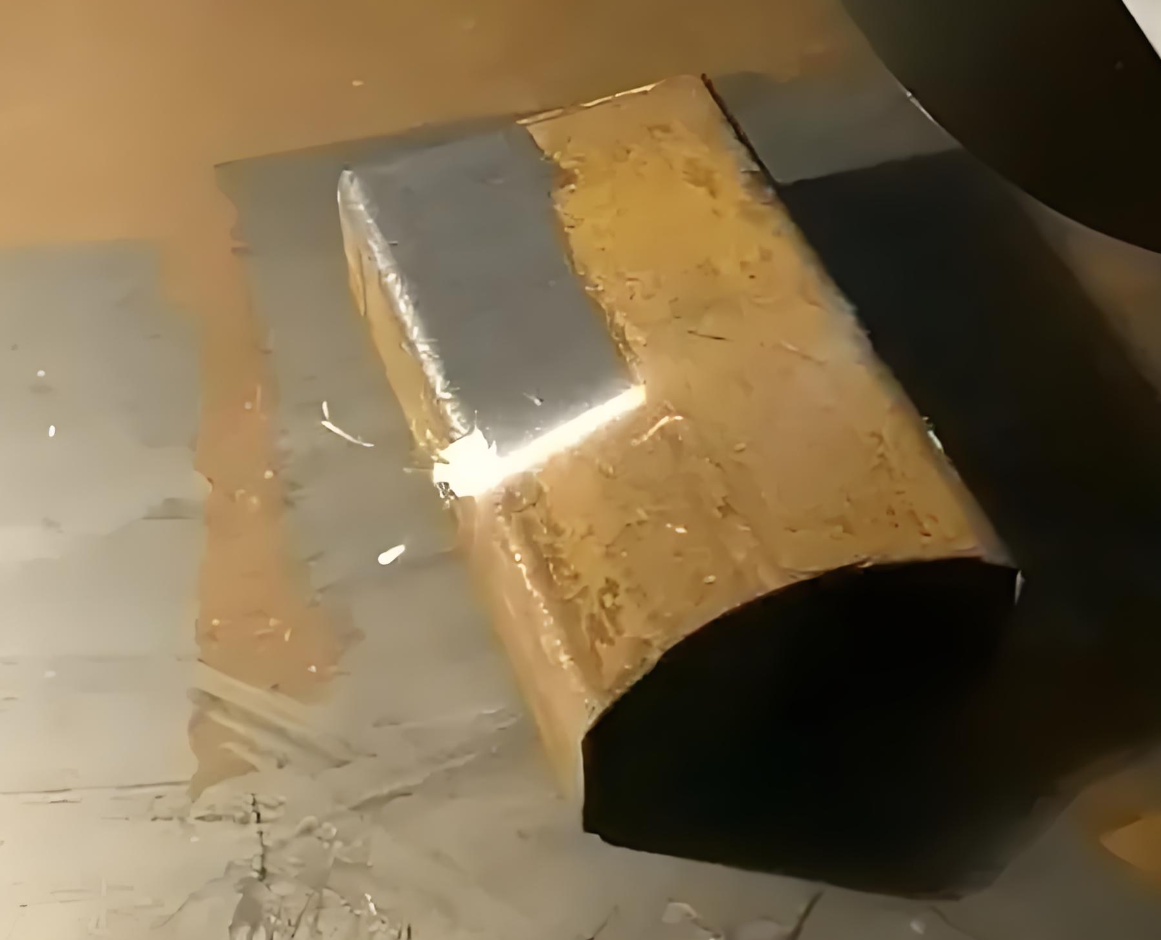

The handheld laser cleaning machine performs well in the field of rust removal.

Sep,22,2024

The handheld laser cleaning machine performs well in the field of rust removal.

It uses the high temperature generated by the laser beam to directly act on the rust layer on the metal surface, causing it to quickly vaporize or peel off, thereby achieving the purpose of rust removal. Here are some of the key features and benefits of handheld laser cleaning machines for rust removal:

Efficient rust removal

The handheld laser cleaning machine can perform rust removal operations at extremely fast speeds, especially for large areas or hard-to-reach rust layers, and its efficiency is particularly obvious. The precise control and high-speed movement capabilities of the laser beam make the rust removal process both fast and thorough.

Non-destructive cleaning

Compared with traditional mechanical rust removal or chemical rust removal methods, handheld laser cleaning machines use non-contact cleaning methods and will not cause any mechanical damage or chemical corrosion to the metal substrate. This makes the cleaned metal surface smoother and flatter, which is beneficial to subsequent painting, electroplating and other processes.

Environmental protection and energy saving

The handheld laser cleaning machine does not need to use any chemicals or water during the rust removal process, so it will not produce waste liquid, exhaust gas and other pollutants, and meets environmental protection requirements. At the same time, the energy utilization rate of the laser beam is high, and the energy consumption of the entire cleaning process is low, which helps to achieve the goal of energy conservation and emission reduction.

High flexibility

The handheld laser cleaning machine is small in size and light in weight, making it easy to carry and operate. It can flexibly adjust parameters such as the power, frequency and scanning speed of the laser beam according to actual needs to adapt to the cleaning needs of rust layers of different thicknesses and materials. In addition, due to its non-contact cleaning characteristics, handheld laser cleaning machines can also perform precise rust removal on complex shapes or hard-to-reach areas.

Wide range of applications

Handheld laser cleaning machines are widely used in the field of rust removal and can be used to remove rust layers on various metal surfaces, such as steel, aluminum alloys, copper, etc. In industries such as shipbuilding, automobile repair, bridge maintenance, and construction engineering, handheld laser cleaning machines play an important role.