WC67K High Efficiency Press Brake Metal Sheets Bending Machine

1.The whole steel welded structure is used to eliminate the internal stress through normalizing and high-frequency vibration to ensure the overall

accuracy of the machine tool, with excellent stiffness and excellent anti-distortion and anti-tilt ability. The thickened workbench plate and the

thickened slider make the whole machine have high rigidity, and the whole machine frame is processed once after welding, so the deformation of

the slider and workbench is very small when bending, and the workpiece has excellent straightness and Angle consistency.

2, Sliding block synchronization mechanism adopts torsion shaft synchronization, mechanical block mechanism, stable and reliable.

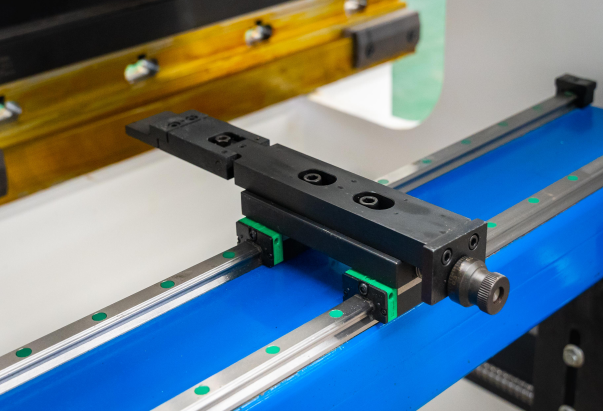

3, The rear stop distance, slide stroke adjustment are driven by servo motor, CNC system control, the rear stop using precision ball screw, linear

guide, synchronous wheel synchronous belt transmission, fast operation, precise positioning data. CNC system adopts two-axis servo control

technology, can set and save a hundred bending program, each program under multiple work step programming.

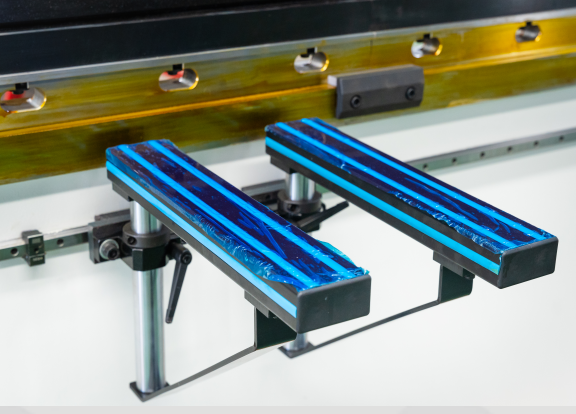

4. The transverse movement of the front supporting arm adopts precision linear guide rail, which can control the distance between the supporting

arm at will, and the supporting arm can adjust the horizontal height, which greatly improves the convenience of workpiece bending.

5, The use of fast clamp clamping bending mold, and equipped with deflection compensation mechanism to ensure a high bending accuracy

(improve the accuracy of the optional hydraulic plus convex table compensation or oblique wedge type mechanical table compensation).

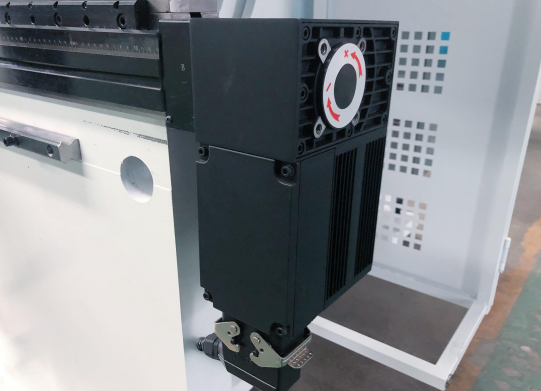

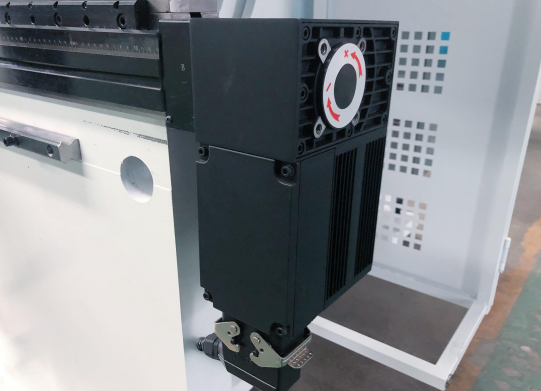

6. The machine tool is equipped with a safety fence device on the left and right side and behind, the electrical cabinet is equipped with an

emergency switch device before and after the door is opened and the power is off, and the foot switch with a protective cover is equipped to

ensure the safe operation during work.

Features:

•Complete steel-welded structure, with sufficient strength and rigidity;

•Hydraulic down-stroke structure, reliable and smooth;

•Mechanical stop unit, synchronous torque, and high precision;

•The backgauge adopts the backgauge mechanism of the T-type screw with smooth rod, which is driven by a motor;

•Upper tool with tension compensating mechanism, In order to guarantee high precision of bending;

•TP10S NC system;

Backgauge configuration:

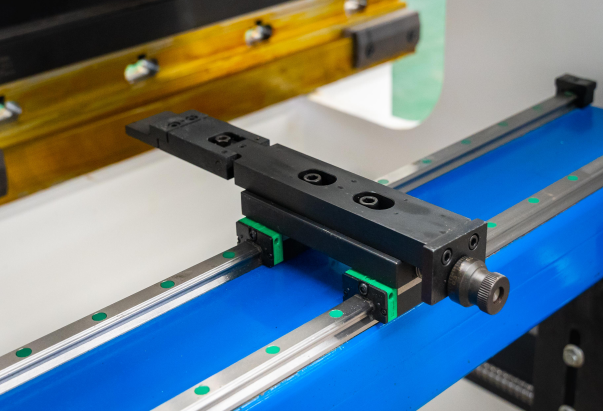

Imported ball screw linear guides are used at the front and rear of the backgauge.

Rail, driven by servo motor, runs accurately and quickly

The crossbeam stop finger moves using double linear guide rails, which ensures high accuracy.

High, easy to move.

Front support rack:

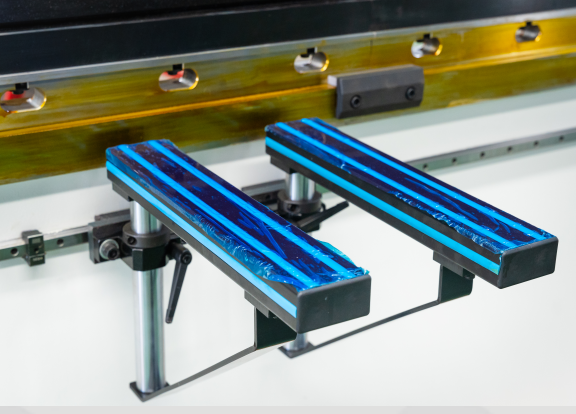

Select The Front Bracket,Horizontal,Adjustment Using Imported Linear Guide Rail

Pressure Gauge:Anti Seismic High-Pressu Repressure Gauge

Heavy Duty Blocking Finger

Electric Machinery Plus Convex Compensation Table