DA-53T 160T4000mm Electro-Hydraulic Press Brake Bending Machine

Delem DA-53T 4+1 axies 160T4000mm Electro-Hydraulic Press Brake Bending Machine

1. Welded steel structure, through normalizing and high-frequency vibration to eliminate stress, to ensure the overall accuracy of the machine, with excellent stiffness, anti-distortion, anti-tilt ability.

2. The master cylinder on both sides belongs to the CNC axis of the electrohydraulic CNC bending machine, among which the Y1 and Y2 axes are synchronously compatible with the hydraulic servo valve imported from Germany and the closed-loop control of the Heidehan grating, and the accuracy of the repetitive slider and parallel accuracy can reach +/-0.01mm.

3. Workbench (V-axis) hydraulic crown automatic compensation system, CNC system automatically adjust the compensation number. (Optional mechanical compensation table structure).

4. The rear gauge (front and rear position) is the X axis in the CNC bending machine, driven by the servo motor and CNC system, driven by the precision ball screw and linear guide rail (users can expand the R axis or R1 axis, R2 axis, Z1 axis, Z2 axis, etc.).

5. Safety guardrails are installed at both ends of the machine.

Front Support Bracket:

Selected Front Rack,Lateral Adjustment Adopts Imported Linear Guide Rails

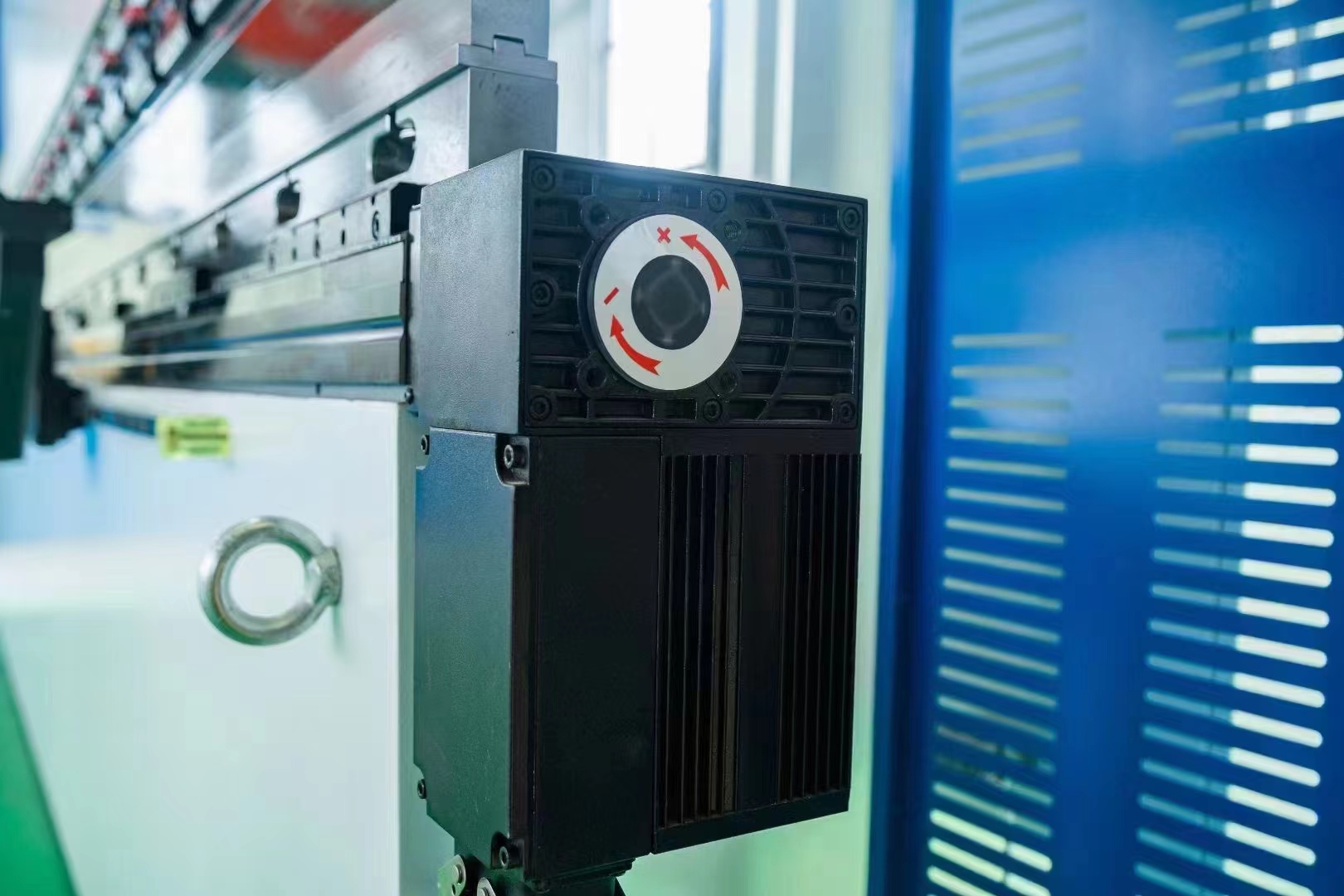

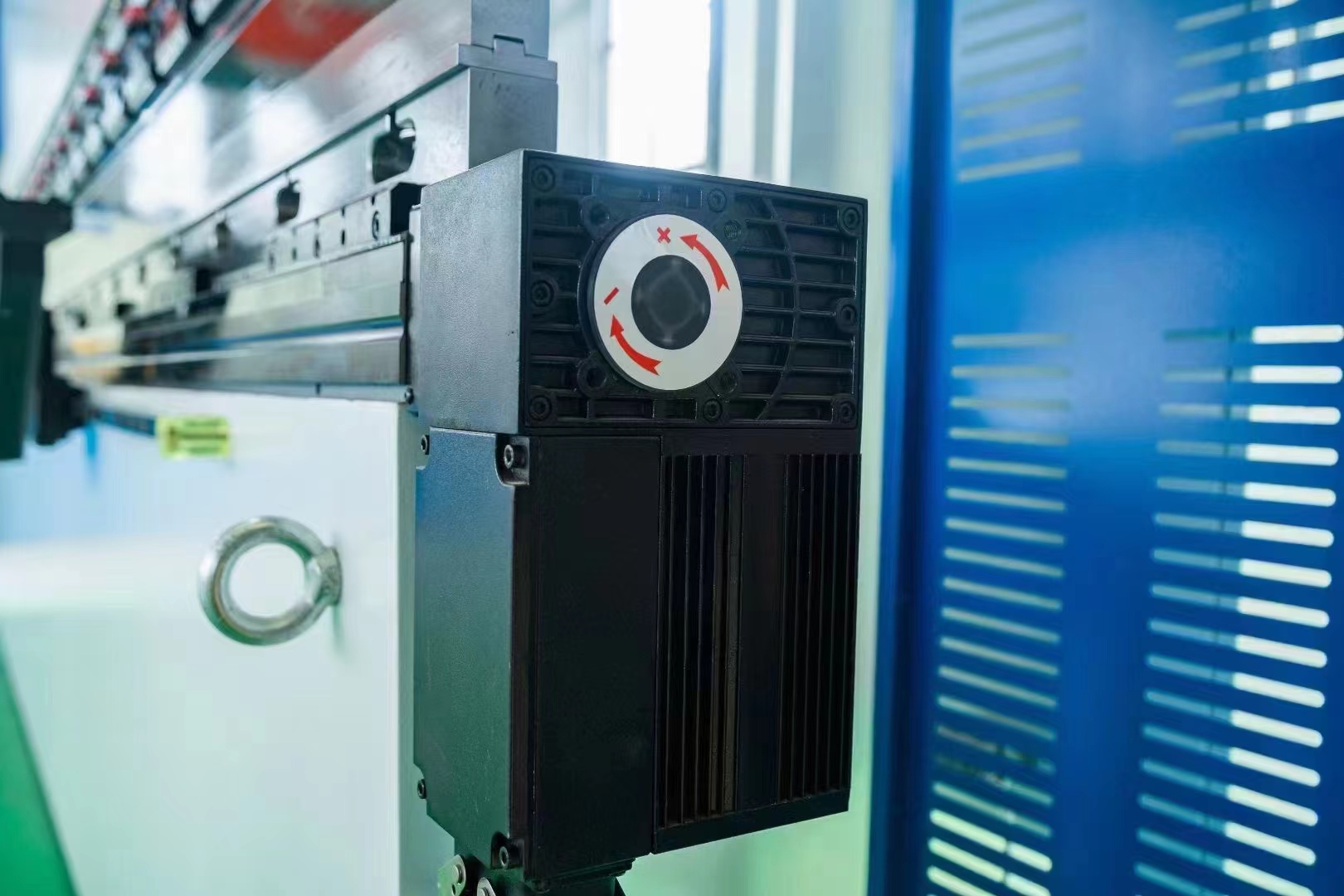

Rexroth Imported Electro-Hydraulic Proportional Valve group:

Electric Gear Control Panel:

Electric and Manual Finger Block Combination:

R-Axis Stopper Lifting Device:

Imported GV Grating Ruler Control Cylinder Stroke:

Electric Machinery Plus Convex Compensation Table: