Pure Electric Bending Machine

Pure Electric Bending Machine widely used in sheet metal industry opens a new trend of all electric servo cnc bending machine and replacing hydraulic cnc press brake.The tonnage and output of all-electric press brake are increasing.

Pure Electric Bending Machine Advantage:

*Servo Drive-Technology Provides High Precision Bending Results

*100%Pure electric power,with no oil.

*Up to 50%less energy consumption compared to a hydraulic press brake.

*Up to 35%faster compared to a hydraulic press brake.

*High efficiency and precision.

*High bending speed and less noise

*Full bending length between side frames.

*Less maintenance cost.

*Friendly user interface.

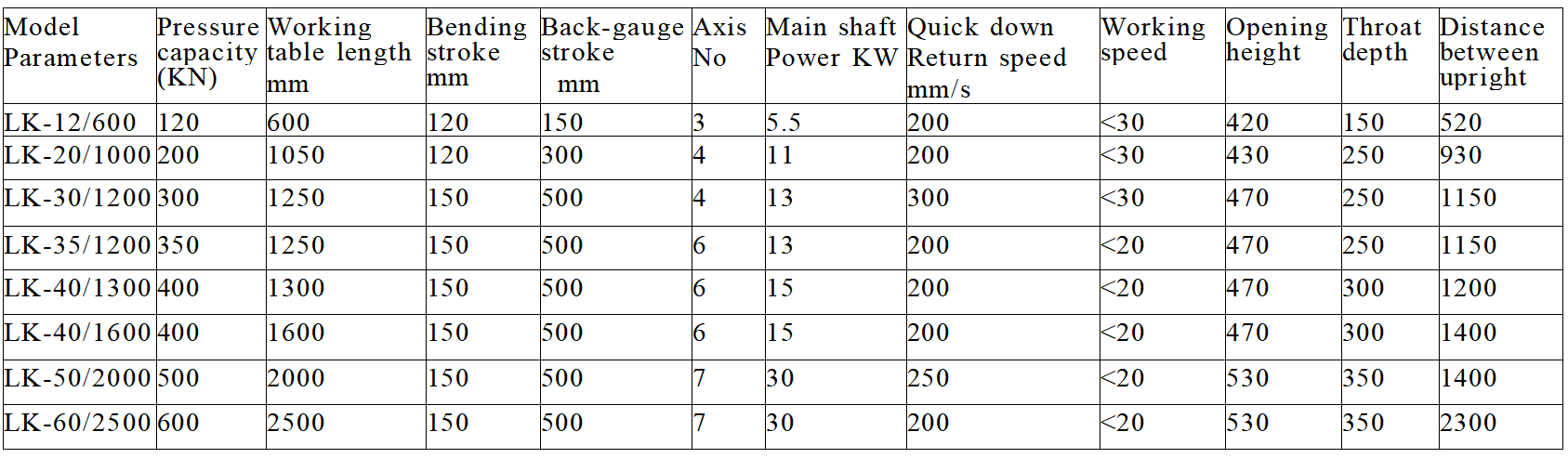

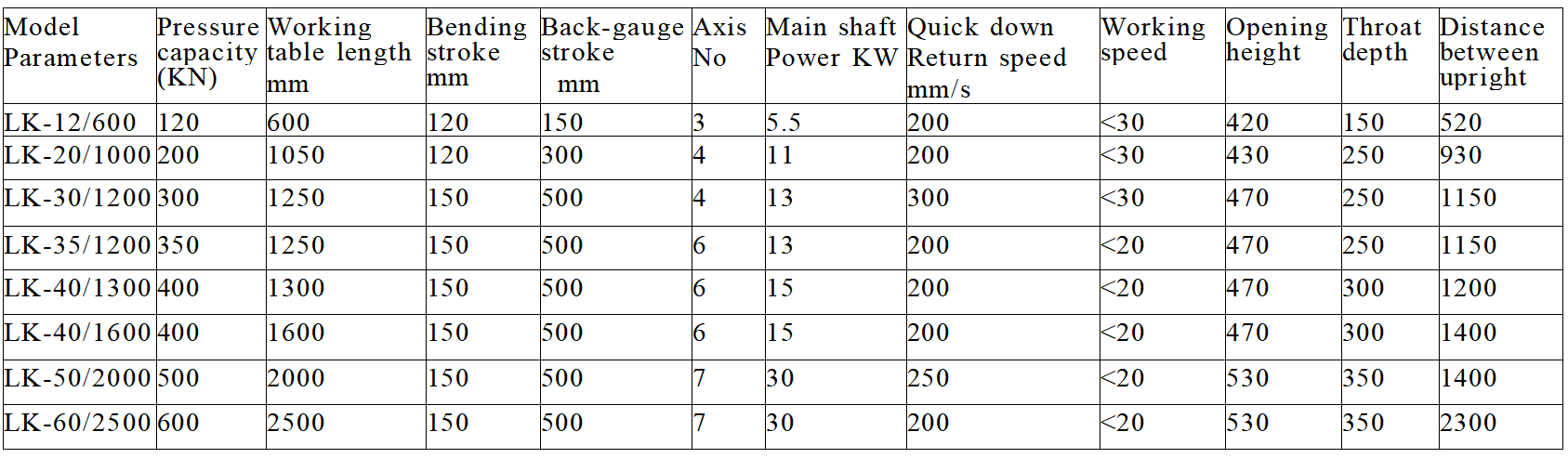

Pure Electric Bending Machine Model And Parameter

Model Parameters | Pressure capacity (KN) | Working Table Length mm | Bending stroke mm | Back gauge stroke mm | Axis No. | Main shaft Power KW | Quick Down return Speed mm/s | Working speed | Opening height | Throat depth | Distance between upright |

LK-12/600 | 120 | 600 | 120 | 150 | 3 | 5.5 | 200 | <30 | 420 | 150 | 520 |

LK20/1000 | 200 | 1050 | 120 | 300 | 4 | 11 | 200 | <30 | 430 | 250 | 930 |

LK30/1200 | 300 | 1250 | 150 | 500 | 4 | 13 | 300 | <30 | 470 | 250 | 1150 |

LK35/1200 | 350 | 1250 | 150 | 500 | 6 | 13 | 200 | <20 | 470 | 250 | 1150 |

LK40/1300 | 400 | 1300 | 150 | 500 | 6 | 15 | 200 | <20 | 470 | 300 | 1200 |

LK40/1600 | 400 | 1600 | 150 | 500 | 6 | 15 | 200 | t20 | 470 | 300 | 1400 |

LK50/2000 | 500 | 2000 | 150 | 500 | 7 | 30 | 250 | 20 | 530 | 350 | 1400 |

LK60/2500 | 600 | 2500 | 150 | 500 | 7 | 30 | 200 | <20 | 530 | 350 | 2300 |

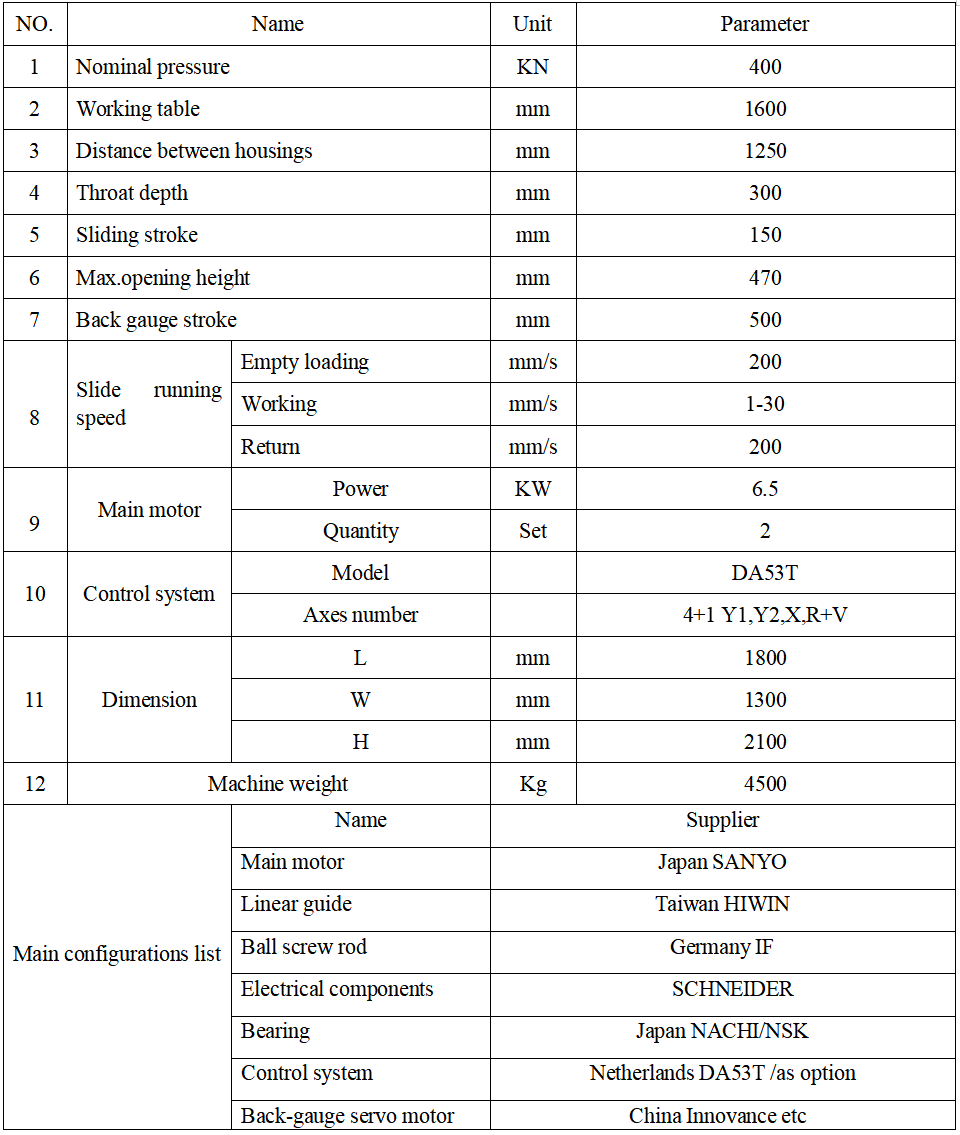

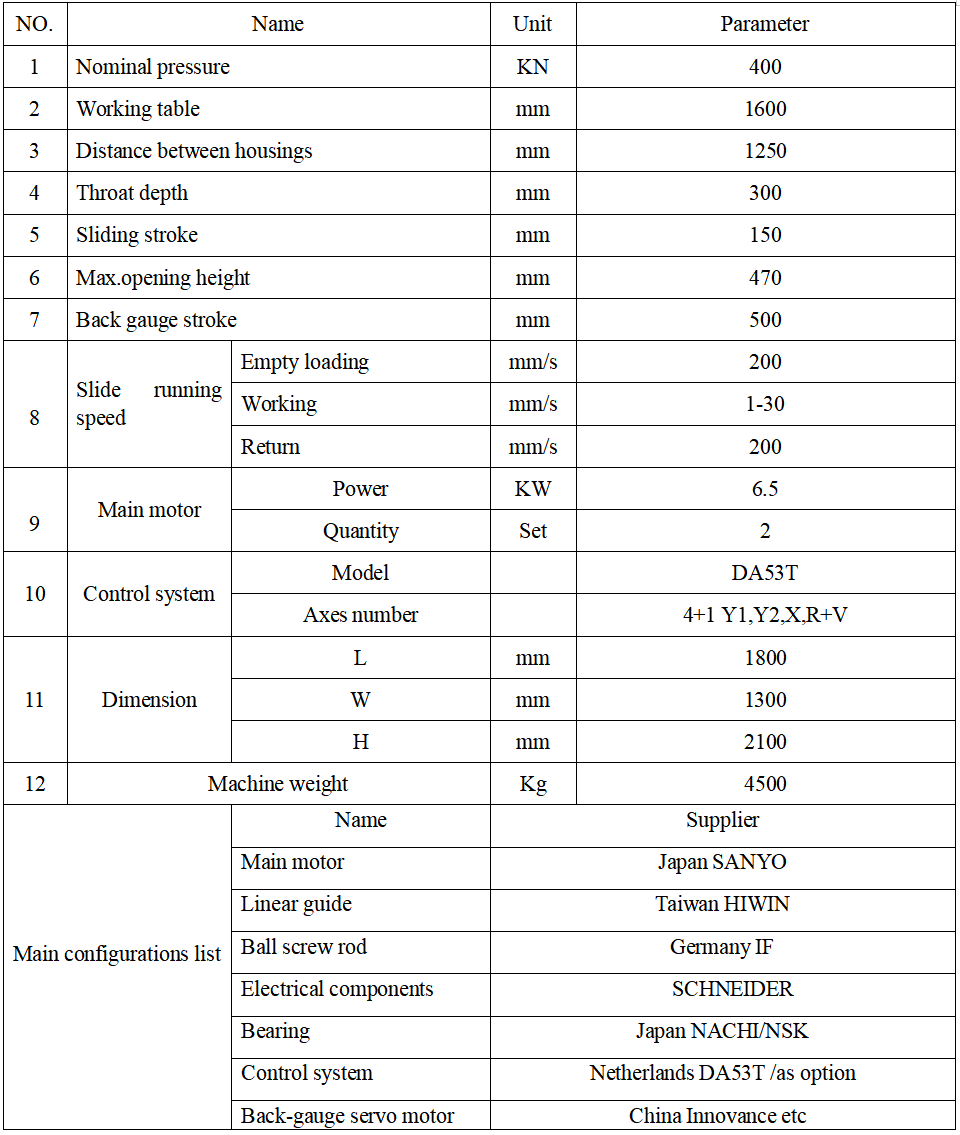

40T1600 Pure Electric Bending Machine specifications as below:

NO. | Name | Unit | Parameter |

1 | Nominal pressure | KN | 400 |

2 | Working table | mm | 1600 |

3 | Distance between housings | mm | 1250 |

4 | Throat depth | mm | 300 |

5 | Sliding stroke | mm | 150 |

6 | Max.opening height | mm | 470 |

7 | Back gauge stroke | mm | 500 |

8 | Slide running speed | Empty loading | mm/s | 200 |

Working | mm/s | 1-30 |

Return | mm/s | 200 |

9 | Main motor | Power | KW | 6.5 |

Quantity | Set | 2 |

10 | Control system | Model |

| DA53T |

Axes number |

| 4+1 Y1,Y2,X,R+V |

11 | Dimension | L | mm | 1800 |

W | mm | 1300 |

H | mm | 2100 |

12 | Machine weight | Kg | 4500 |

Main configurations list | Name | Supplier |

Main motor | Japan SANYO |

Linear guide | Taiwan HIWIN |

Ball screw rod | Germany IF |

Electrical components | SCHNEIDER |

Bearing | Japan NACHI/NSK |

Control system | Netherlands DA53T /as option |

Back-gauge servo motor | China Innovance etc |

Main technical indicators and functions:

l Y1/Y2 adopts full-closed-loop control mode of grating scale or magnetic scale feedback, precise positioning control, repeat positioning;

lIntelligent tool loading monitoring ensures tool safety;

l Accuracy reaches ±3μm;

lThe five-line touch screen, the service life of more than 10 million times high and reliable, the operation process is simple and fast;

lThe automatic calculation function of the bending pressure, exceeding the stress limit range alarm prompt;

lCalculating function of the "Direct" calculation function of the back gauge: according to the size and plastic deformation of the sheet metal, calculate the back gauge position directly according to the neutral layer;

lAngle intelligent compensation function: according to sheet metal material characteristics, mold size, material thickness, bending angle and other sheet metal process parameters, combined with the numerical control system angle calculation model, any sheet metal only needs one trial bending, and it can be automatically corrected according to the angle deviation , can be formally produced;

lArc continuous bending function;

l Mold parameter library: establish a mold parameter library for customers, so that customers can quickly call parameters for sheet metal bending.

Back gauge

The standard configuration is two-axis (X, R) CNC floor-standing back gauge, and two-axis (X, R), four-axis (X, R, Z1, Z2), six-axis (X1, X2, R1, R2, Z1, Z2) are optional according to customers’ demands.